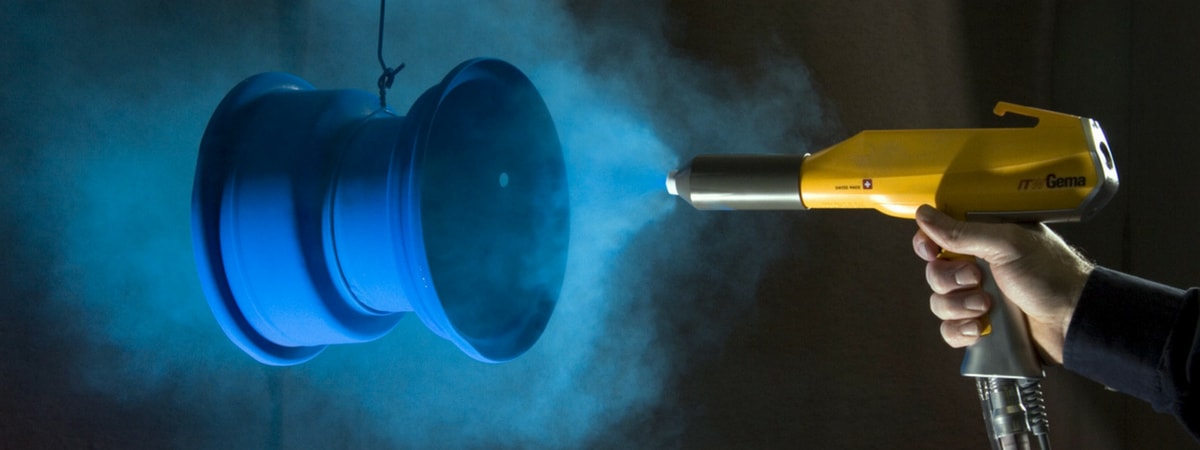

The basis for any good coating is Surface Preparation. The majority of powder coating failures can be traced to non-preparation of the surfaces.

We at Annai Colour coatings, firmly believe in proper surface preparation. We follow a correct sequence of a schematic layout of Phosphating and Chromating pre-treatment system. This is done to avoid any failures on post-finishing of powder coating. It is worth mentioning that the processes we follow are approved by the Pollution Control Board.

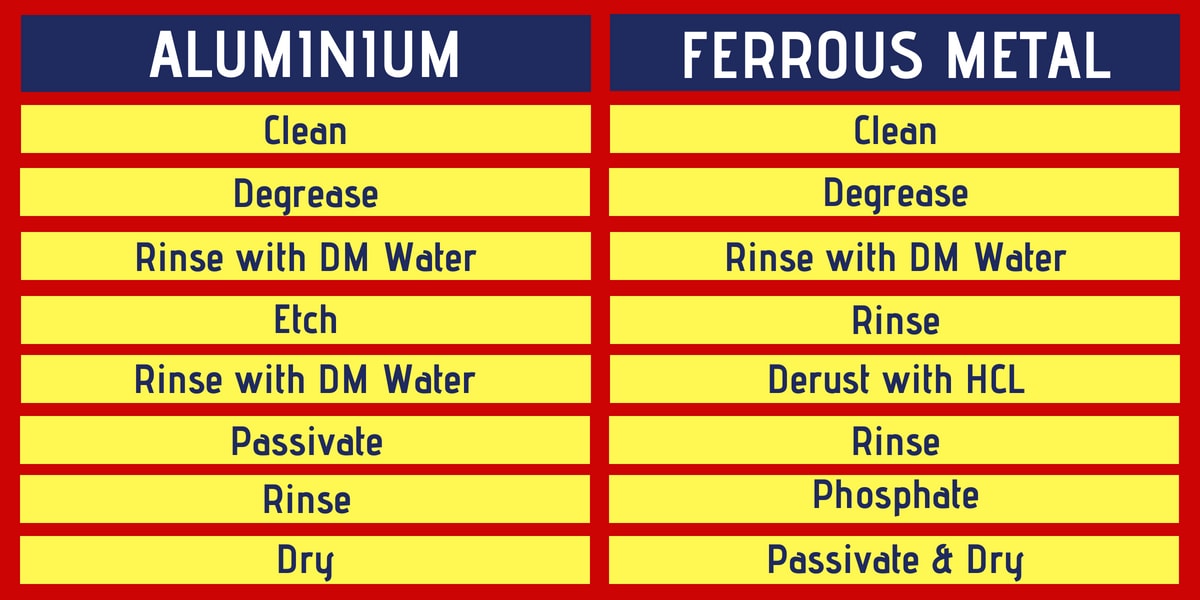

The surface treatment is different for different materials. The surface treatment for Aluminium and Ferrous metals are sequenced below: